Enhancing Production Efficiency with High-Quality Banana Rollers

In the world of industrial machinery, efficiency, durability, and customization play vital roles in ensuring production lines run smoothly. One essential component that contributes significantly to these aspects is the banana roller. Though often overlooked, banana rollers are critical in web guiding systems for applications involving films, paper, textiles, and more. Choosing a reliable Banana Roller Supplier is essential to maintain the consistency and quality required in today’s competitive manufacturing environment.

What is a Banana Roller?

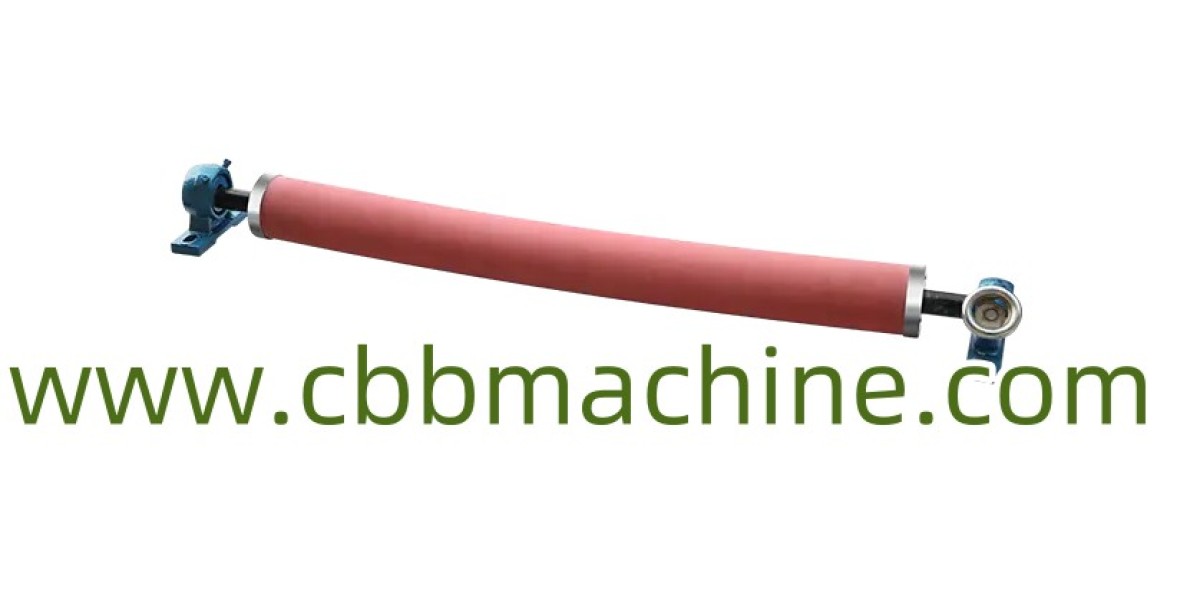

A banana roller, also known as a bowed roller or curved roller, is a specially designed roller used to remove wrinkles, eliminate slack, and spread out materials during processing. Its curved shape allows it to exert controlled tension across the material’s width, effectively smoothing it out without causing damage or distortion. Banana rollers are especially useful in continuous production lines where materials such as plastic film, aluminum foil, and textiles are being wound or unwound.

The design and function of banana rollers make them indispensable in many industries, including packaging, printing, laminating, and non-woven fabric production. As such, manufacturers seek a Banana Roller Supplier who can offer customizable solutions to meet specific technical requirements and performance standards.

Key Features of a Quality Banana Roller

When selecting a banana roller for your production system, certain features distinguish high-quality rollers from standard options:

Precision Engineering

A well-manufactured banana roller is precision-engineered to maintain a consistent bow and tension distribution. This prevents material deformation and ensures smooth handling even at high speeds.

Durability

High-quality materials such as aluminum alloy, stainless steel, or carbon steel are often used to build banana rollers. Surface treatment options, such as anodizing or chrome plating, can be applied to extend roller life and resist wear and corrosion.

Customizability

Since each production line has unique requirements, the ability to customize the roller’s dimensions, bow radius, surface treatment, and mounting style is essential. A professional Banana Roller Supplier will offer solutions tailored to fit your equipment specifications and processing needs.

Low Maintenance

Properly balanced and engineered banana rollers are low maintenance. They operate with minimal vibration and require infrequent adjustments, which saves time and reduces downtime on the production line.

Applications Across Industries

Banana rollers are used in various industries to optimize the handling of materials and improve final product quality:

Plastic Film and Flexible Packaging

In the production of stretch film, shrink wrap, and laminated film, banana rollers prevent wrinkling and maintain flatness, ensuring smooth lamination and printing.

Paper and Printing

For paper converting and high-speed printing applications, banana rollers help avoid creases and misalignment, contributing to better print registration and cleaner output.

Textile Industry

In fabric processing and finishing, banana rollers keep materials tensioned and flat, improving fabric quality and reducing waste.

Non-Woven Materials

For hygiene products and industrial fabrics, banana rollers provide the necessary web control to maintain consistency during production.

Selecting the Right Banana Roller Supplier

Choosing the right Banana Roller Supplier is crucial to ensuring your production line performs at its best. A reliable supplier should not only offer high-quality products but also provide technical support, customization options, and timely delivery. Working with an experienced supplier gives manufacturers peace of mind that their machinery will operate efficiently with minimal interruptions.

A good supplier will:

Understand the specific challenges in your production process.

Offer customized design and manufacturing services.

Ensure quality control through stringent inspection procedures.

Provide after-sales support and guidance on installation and maintenance.

It is also important to choose a supplier who is responsive and knowledgeable, as their insights can often help optimize your setup or resolve minor issues before they escalate.

Future Trends and Innovation

As industries push for greater automation and smarter production lines, banana roller technology continues to evolve. Modern banana rollers are being integrated with sensors and advanced coatings to improve lifespan and provide real-time feedback on performance. By partnering with a forward-thinking Banana Roller Supplier, manufacturers can stay ahead of technological advancements and remain competitive in their respective markets.

Conclusion

Banana rollers are essential components in material processing industries. Their ability to control tension, eliminate wrinkles, and maintain material alignment plays a significant role in improving production quality and efficiency. Choosing the right Banana Roller Supplier ensures that you receive a product tailored to your operational needs and built to withstand the demands of modern manufacturing.

Manufacturers looking to enhance their production lines should invest time in selecting a supplier who offers not only a durable and efficient product but also ongoing support and customization capabilities.