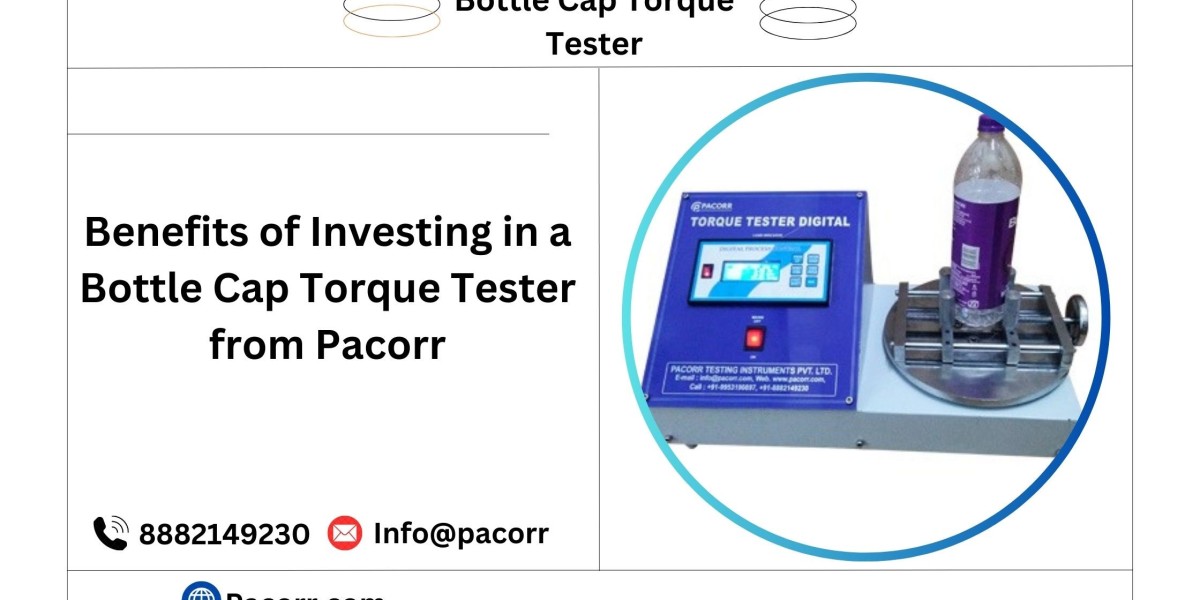

What is a Bottle Cap Torque Tester?

A Bottle Cap Torque Tester measures the force required to open or close a bottle cap. This ensures that the cap provides a secure seal while remaining easy to open for the end-user. By conducting torque tests, manufacturers can guarantee the quality and usability of their packaging while reducing risks of leaks, spoilage, and customer dissatisfaction.

Why is Torque Testing Essential?

Packaging integrity is non-negotiable when it comes to consumer products. Torque testing ensures the following:

- Leak Protection: Prevents product spillage during storage or transportation.

- Safety Assurance: Confirms the cap is securely tightened to maintain product safety.

- Consumer Usability: Ensures the cap is easy to open without excessive effort.

- Compliance: Adheres to industry standards and regulations for packaging quality.

Pacorr’s Bottle Cap Torque Tester: Features That Set Us Apart

Pacorr’s Bottle Cap Torque Tester offers precision and reliability, making it a top choice for quality control. Here’s what makes it exceptional:

- Accurate Measurement: Advanced sensors deliver precise torque readings.

- Versatile Design: Compatible with various cap types, including plastic, metal, and glass.

- Easy Operation: User-friendly interface and digital display simplify testing.

- Adjustable Settings: Customize torque limits for specific products.

- Durable Build: Engineered for longevity, even in high-production environments.

- Data Management: Integrated storage and export features for quality reporting.

Applications Across Industries

The Bottle Cap Torque Tester serves numerous industries, including:

- Beverages: Ensures secure seals for carbonated drinks, juices, and water bottles.

- Pharmaceuticals: Confirms tamper-proof packaging for medicines and syrups.

- Cosmetics: Validates leak-proof seals for lotions, oils, and creams.

- Food: Maintains freshness for sauces, dressings, and condiments.

- Chemicals: Prevents hazardous leaks for chemical and industrial products.

How to Use Pacorr’s Bottle Cap Torque Tester?

- Secure the bottle in the tester.

- Adjust grips to fit the bottle size.

- Select the desired test mode (opening or closing torque).

- Rotate the cap using manual or automatic operation.

- Record the torque measurement displayed on the screen.

- Compare results against specified standards for quality assurance.

Benefits of Choosing Pacorr

- Expert Engineering: Years of experience in quality testing equipment.

- Tailored Solutions: Options designed for specific industrial needs.

- Compliance Assurance: Meets global standards like ISO and ASTM.

- After-Sales Support: Comprehensive training and customer service.

Why Quality Control Matters

Investing in tools like the Bottle Cap Torque Testing not only ensures product integrity but also builds trust with your customers. Proper torque testing reduces waste, prevents recalls, and safeguards your brand’s reputation in the market.

Explore Pacorr’s Testing Solutions

At Pacorr, we are committed to helping businesses achieve excellence through cutting-edge testing equipment. Our Bottle Cap Torque Tester is just one example of our dedication to quality control. With innovative features and robust performance, Pacorr’s solutions help you deliver reliable products every time.